Equipment

Plating Line

Ultra-high precision

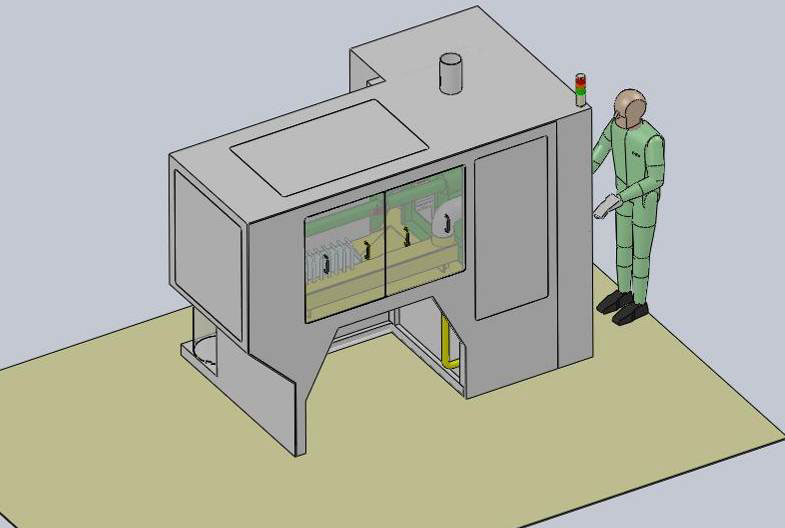

Au Spot Semi Auto Plating Line

Compatible with a ultra-high precision Au Spot Plating that can not be achieved by Reel to Reel plating type. Compatible with strip type material

Auto Hoop Cu/Ni/Au/Ag plating line

selective plating (Partial plating),

Possible to plate SUS & Any Cu materials (inline automatic image inspection device)

Auto Hoop Ni/Cu/Sn Plating Line

with Reflow Treatment

Possible to plate Any Cu materials & Fe (inline automatic image inspection device)

Auto hoop Cu/Ni/Au/Sn plating Line

with Reflow treatment

Possible with material width up to 110mm and material thickness up to 1.5mm is possible (inline automatic image inspection device)

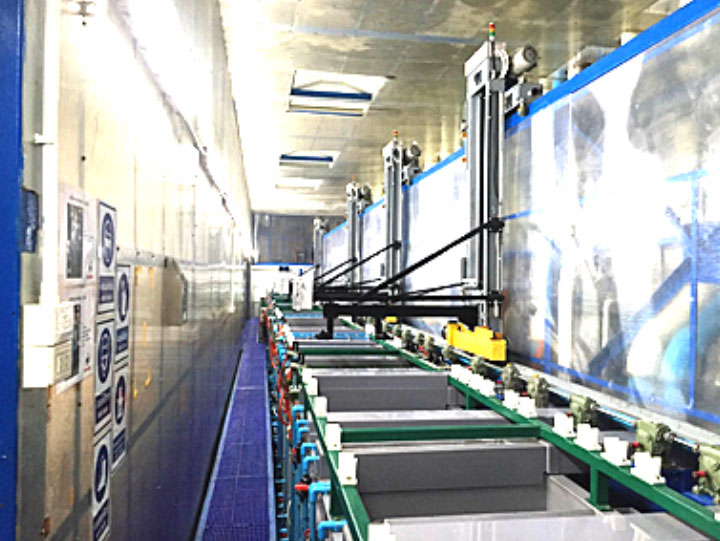

Auto Electroless Nickel

Electlytic Nickel Plating Line

- Material: SUS & Iron

- Plating Tank: 9 stage

- Total Tank: 37

- Robot: 5 unit

- Total length: 30.75m

Auto Electrolytic Cu/Ni/Sn Plating Line

(Dull, Semi bright, Bright)

- Material: Copper, Brass, Iron

- Plating Tank: 10 plating tank

- Total Tank: 38

- Robot: 5 units

- Total length: 30.0 m

Auto Electroless

Nickel Plating Line

- Material: Iron (Fe), SUM, SK

- Plating Tank: 6 stage

- Total Tank: 28

- Robot: 4 unit

- Total length: 25.0m

Multi-Manual Plating Line

It’s a manual type line, but have enough control systems.

- Material: Iron, SUS, Brass, Copper

- Plating Tank: 3 & 4 stage

- Total Tank: 23& 28 ( TTL 51tanks)

- Robot: Hoist

- Total length: 23.0m

Electrolytic Tin/Bi Plating

Electrolytic Nickel plating

Electrolytic Tin plating

Electroless Nickel plating

Electrolytic Hard Bright Silver Plating

Auto Rack/Barrel Plating Line

It can be dispatched Rack JIG & Barrel at the same time.

Rechargeable for barrel machine (Oil-free)

- Material: Iron,SUS

- Plating Tank: 9 stage

- Total Tank: 37

- Robot: 4 unit

- Total length: 25.5m

Electrolytic Semi Bright Nickel plating

Electrolytic Bright Nickel plating

Electroless Nickel plating

Auto Electlytic Au

Spot Spagaer Plating Line

- Material: Cupper + Nickel

- Plating Tank: 1 stage

- Total Tank: -

- Robot: -

- Total length: 10.0m

Electro Nickel Plating Line

- Material: Cupper

- Plating Tank: 8 stage

- Total Tank: 39

- Robot: 4 unit

- Total length: 25.0m

Patent Line

Auto SCE (Super Chemical Etching)

- Material: AL

- Plating Tank:

- Total Tank: -

- Robot: Conveyor Chain Drive

- Total length: - m

Chemical Conversion line

Special treatmetment for improve the Vulcanization adhesion

- Material: Al & ADC-12

- C/V Tank: 1 stage

- Total Tank: 14

- Robot: Manual Type (Hoist)

- Total length: 12.5 m

Scale removal of lost wax casting products

Scale & Casting sand removal of lost wax casting products

- Material: SUS etc...

- Treatment Tank: 10 Tank

- Total Tank: 10

- Robot: Manual type (Hoist)

- Total length: 30.0m

Auto Chemical Polishing/ EN-P, Bright Ni / Ni/Sn Black plating for High Quality fish-hook line

- Material: High Carbon Steel

- Plating Tank: 20 stage

- Total Tank: 36

- Robot: 5 unit

- Total length: 25.0m

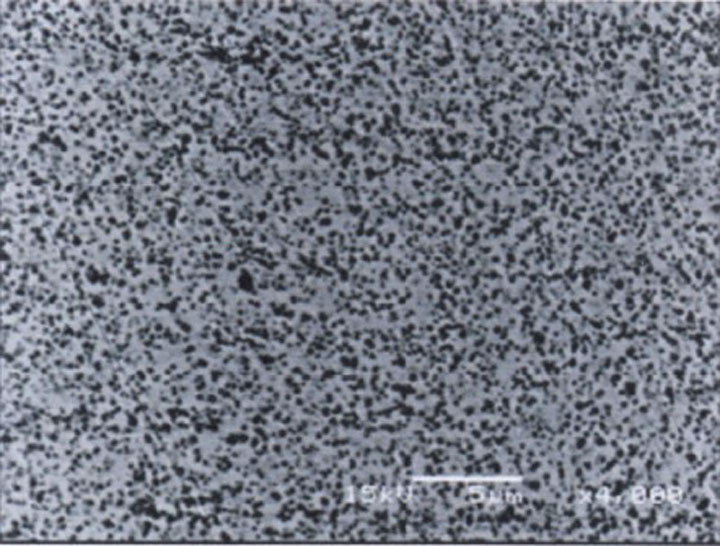

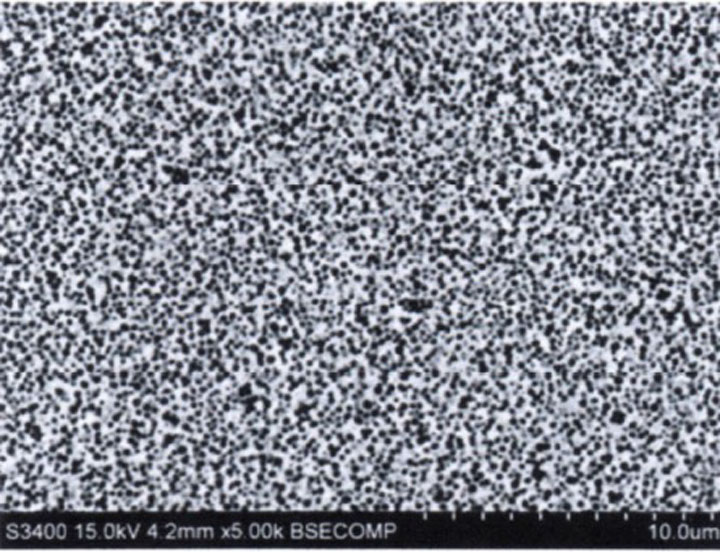

Electroless PTFE Plating Line

(PTFE 30 - 40% vol %)

Polytetrafluoroethylene

- Material: Iron & Cu

- Plating Tank: 3 stage

- Total Tank: 18

- Robot: Manual Type (Hoist)

- Total length: 18.5m

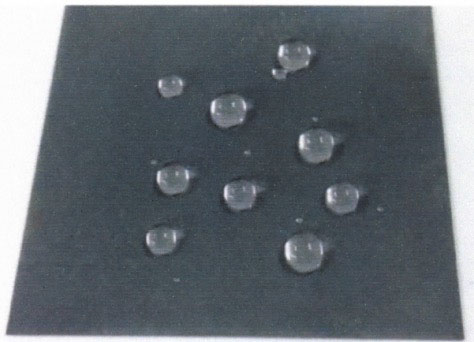

Superiority in functionality

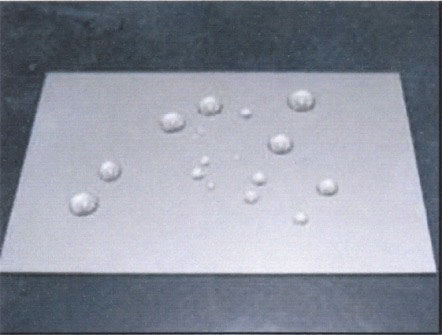

Water repellency

Sliding property

Smoothness property

Dirt adhesion prevention

PTFE eutectic amount 20 ~ 26 vol%

Water repellency.

Angle of contact : About 110 degrees

PTFE eutectic amount 20 ~ 26 vol%

Water repellency.

Angle of contact : About 115 degrees

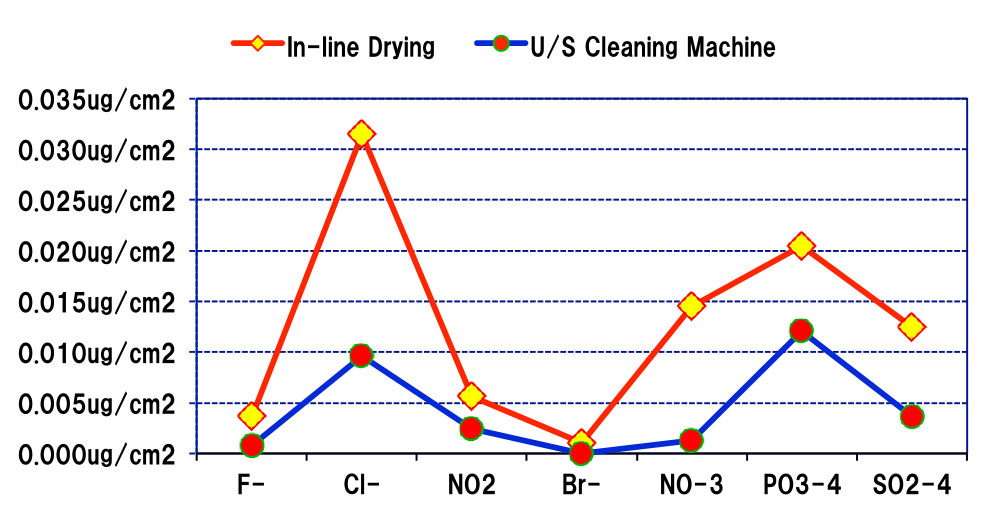

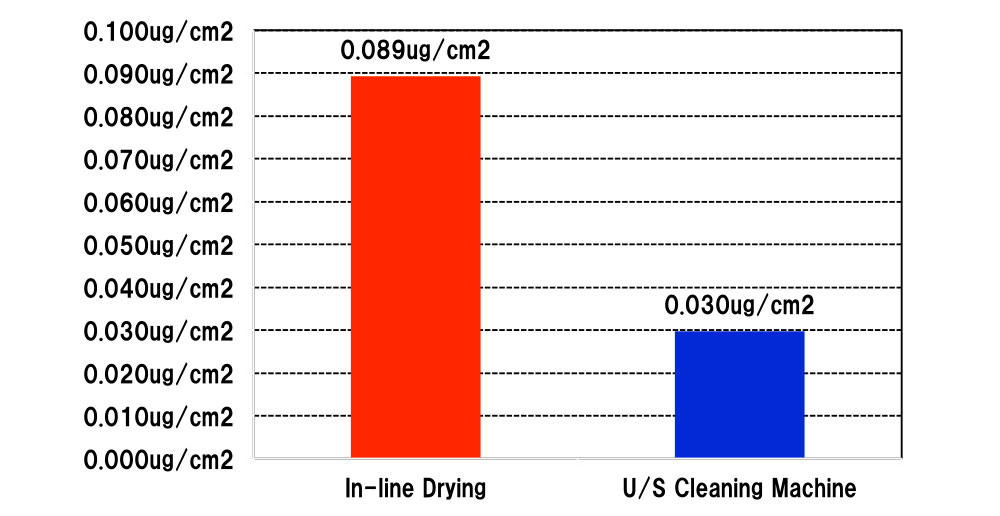

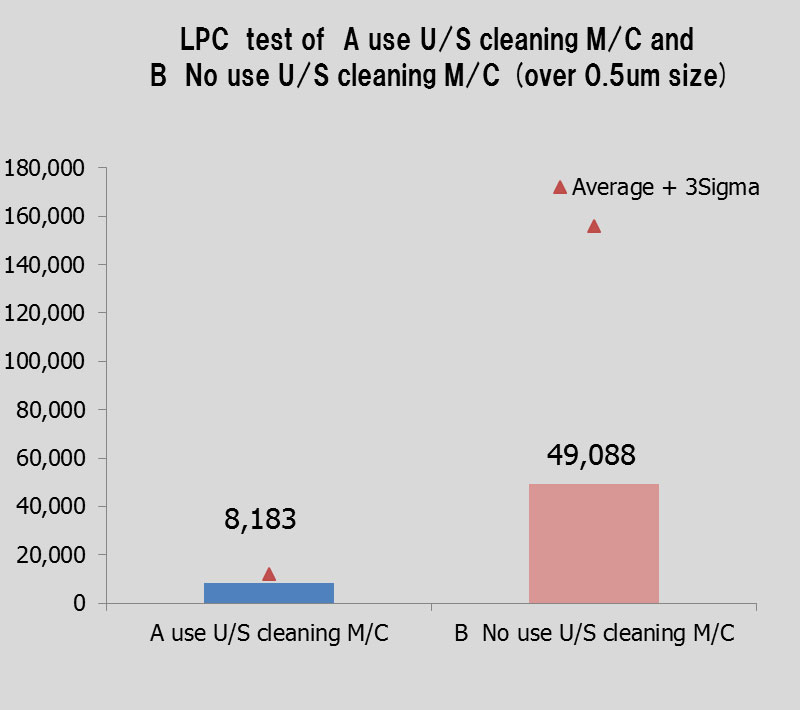

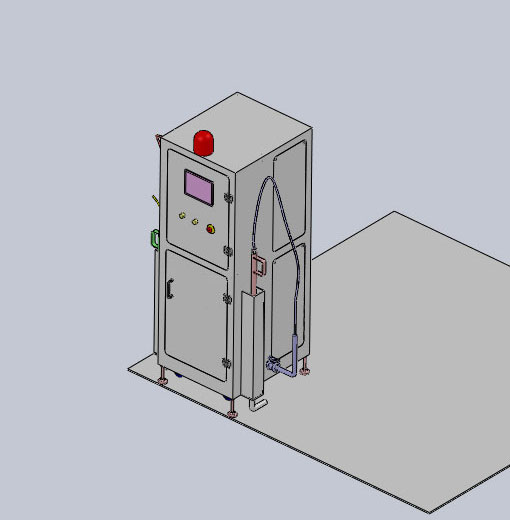

Countermeasure of IC (ion contamination) & Particle pollution after plating.

Products will be cleaning and drying immediately at offline after plating.

This special washing machine is used to final wash for semiconductor products.

Inside ultra D.I water quality is 3 ~ 18MΩ ( 0.33us/cm2 – 0.05us/cm2) only be used.

Process

DI water shower Ultrasonic cleaning DI water shower Blower drying (HEPA filter 0.3um).

It's possible to significantly improve the LPC and ionic contamination as result.

Countermeasure of LIQUID PARTICLE COUNTER (LPC)

- LIQUID PARTICLE COUNTER REPORT -

- Subject: LPC test of A (U/S cleaning M/C) and B (No U/S cleaning M/C)

- Part Name: N/A Surface area per pcs : 0.11dm2 x 10pcs = 1.10dm2 (110cm2)

- Part Number: N/A

- Lot Number: N/A

- Measuared by: Onchisa (May 08, 2015)

- Checked by: Onchisa (May 08, 2015)

- Remarks: Target over 0.50um particle size.

| Test Sample No. |

A use U/S cleaning M/C Counts/Part |

B use no U/S cleaning M/C Counts/Part |

|---|---|---|

| No.1 | 9,283 | 22,583 |

| No.2 | 8,967 | 61,833 |

| No.3 | 8,883 | 28,917 |

| No.4 | 7,883 | 31,017 |

| No.5 | 9,450 | 34,650 |

| No.6 | 8,250 | 84,717 |

| No.7 | 7,817 | 73,450 |

| No.8 | 9,383 | 9,367 |

| No.9 | 5,867 | 21,617 |

| No.10 | 6,050 | 122,733 |

| AVERAGE | 8,183 | 49,088 |

| TOTAL | 81,833 | 490,883 |

| MAX. | 9,450 | 122,733 |

| min. | 5,867 | 9,367 |

| R | 3,583 | 113,367 |

| Sigma | 1,313 | 35,631 |

| 3 Sigma | 3,938 | 106,892 |

| Average + 3 Sigma | 12,121 | 155,980 |

Note: Sampler size over 0.5um

Ecologically friendly Technology

1. Hydrochloric Acid Recovery Machine

Area : 0.65m(L) x 0.8m(W) x 1.8m(H)

Assume Fe3+ content is 2 g/L before treatment

Operation Flowrate : 60 L/hr

Circulation Type 2units & Batch Type 1unit

It possible to be used semi-permanently without renewal HCl bath by continuous circulation between this machine and hydrochloric acid bath with filter.

2. Nickel Recovery Machine

Area : 2.7m(L) x 1.5m(W) x 2.0m(H)

Operation parameter:

Capacity : 100 ton/month

EN inlet flow rate: 250 L/hr

NaOH dosing rate: 20 L/hr

Water flow rate :240 L/hr

Max. treatment speed : 330 L/hr

NaOH consumption : 8 ton/month

Water consumption : 96 ton/month

Nickel recovery machine is original development very compact machine, made it possible to mass processing by automatic continuous operation.